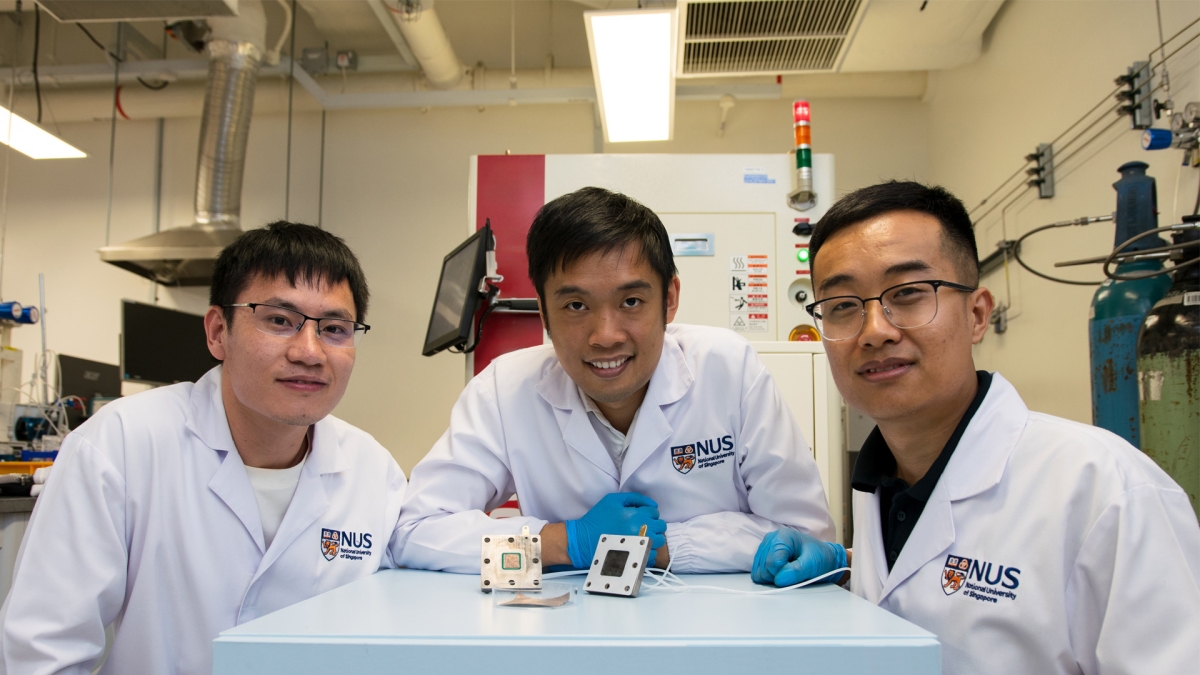

Asst Prof Lum Yanwei (centre), Dr Wang Bingqing (left), and Mr Wang Meng (right) from NUS Dept of Chemical and Biomolecular Engineering have developed an energy-efficient, cost-effective way to convert carbon dioxide from flue gas into value-added chemicals and fuels. (Photo from NUS)

Asst Prof Lum Yanwei (centre), Dr Wang Bingqing (left), and Mr Wang Meng (right) from NUS Dept of Chemical and Biomolecular Engineering have developed an energy-efficient, cost-effective way to convert carbon dioxide from flue gas into value-added chemicals and fuels. (Photo from NUS)

New NUS technique efficiently transforms carbon into high-value chemicals

This reduces the cost of conversion by 30%.

Researchers from the National University of Singapore (NUS) have developed a new technique to convert waste carbon dioxide into value-added chemicals and fuels.

The team was led by Assistant Professor Lum Yanwei from the Department of Chemical and Biomolecular Engineering under the NUS College of Design and Engineering.

The experts’ discovery allows direct conversion of carbon dioxide from treated flue gas, which is a common by-product of industrial processes, into high-value multi-carbon (C2+) products such as ethylene and ethanol that are used to produce compounds like plastics, polymers and detergents.

Not only will this technology make the process more efficient, but also cost-effective, NUS said.

"The cost of purifying CO2 can amount to about US$70 to US$100 per ton, which can constitute about 30% of the costs involved in converting CO2 to feedstocks such as ethylene through electrochemical means,” Lum said.

"Our novel technique demonstrates a potential pathway for the development of efficient electrolysers for the direct conversion of CO2 in flue gas, using simple yet effective electrolyte and catalyst design strategies to advance integrated sustainability solutions," he added.

According to the researchers, the technique can still be adjusted to also be used in synthesising other chemicals, like acetate and propanol that are used in the production of products such as adhesives and disinfectants, respectively.

ALSO READ: Targeted brain stimulation trials aim to improve management of treatment-resistant depression

"We are seeing strong interest from the industry and are currently in talks with some companies to further advance this research," Lum said. "Our goal is to enhance the energy efficiency and scalability of our system, moving beyond laboratory-scale experiments towards developing prototype reactors that can be applied in industrial settings."

Advertise

Advertise