SATS launches virtual kitchen for in-flight catering production

It captures and integrates process data into a 3D virtual environment.

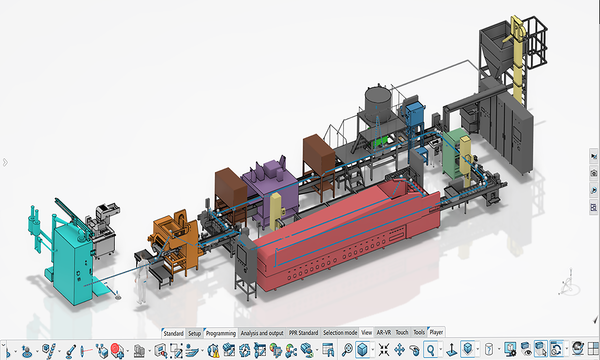

SATS, in partnership with French software company Dassault Systemes, implemented what it claims to be the world’s first virtual kitchen as part of its efforts to enhance in-flight kitchen operations.

Also read: SATS Q1 profits down 14.4% to $54.7m

The food solution and gateway service provider utilises Dassault Systèmes’ 3DEXPERIENCE platform on the cloud to create a 3D digital twin experience of a virtual kitchen that pairs virtual and physical operations to provide data-driven analytics in order to improve resource planning.

The technology allows SATS to simulate different food production processes in order to improve capacity planning and production scheduling, prevent bottlenecks, and enhance productivity. SATS is also able to better forecast ingredient usage in its large-batch food production to reduce food wastage.

The virtual kitchen integrates all process data and information into one 3D virtual environment to ensure consistency and also serves as a collaborative workspace that fosters social innovation and increases productivity, where employees across business processes can share knowledge.

“The use of digital twin technology helps SATS to simulate different production scenarios and cooking processes to optimise resources within our kitchens,” Albert Pozo Hernandez, Chief Digital Officer, SATS, said in a statement.

Photo credit SATS Ltd. SATS collaborated with Dassault Systèmes to create a virtual simulation of its automated rice line for in-flight catering production to optimise resource planning.

Advertise

Advertise